Concrete buckets

Conical concrete skip with bottom-side discharge and forklift pockets

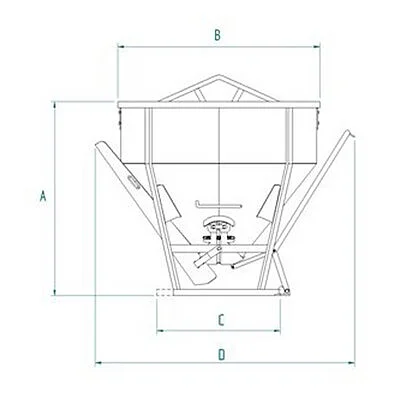

CL-STConical concrete bucket with central and side discharge, equipped for forklift handling

The CL-ST conical concrete bucket model, with both central and lateral twin-valve discharge operated by lever and fork base, represents a highly advantageous choice for several reasons:

Application sectors:

Finish Type:

Painted

Versions available

| Code | Image | Active variant image | Capacity (kg) | Capacity (L) | Weight (kg) | Adjustment (mm) | Internal Pipe Ø (mm) | Max opening (mm) | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Dimension D (mm) | Dimension E (mm) | Dimension F (mm) | Dimension G (mm) | Dimension H (mm) | Dimension I (mm) | Dimension L (mm) | Dimension M (mm) | Length (mm) | Width (mm) | Height (mm) | Motor | Frequency (Hz) | Speed (rpm) | Blade Ø (mm) | Max. cutting H (mm) | Engine power (cv) | Blade diameter (mm) | Power supply (V) | Useful height (mm) | Total height (mm) | Base diameter (mm) | Diameter (mm) | No. of 200L drums | No. of 1000L tanks | Max load (daN) | Loading opening (mm) | Max liquid temperature (°C) | Max. pipe length (mm) | Cutting width (mm) | H Cut (mm) | Minimal cut | H Wheels (mm) | Technical data notes | Image Name | No. of legs | No. of people | Pubblica nel sito web | Min. capacity (kg) | Max. capacity (kg) | Min. length (mm) | Max. length (mm) | No. of elements (mm) | Span (mm) | Products | Custom price lists | Request Info |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CL-15ST | 390 | 150 | 95 | 620 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-20ST | 520 | 200 | 100 | 700 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-25ST | 650 | 250 | 105 | 780 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-30ST | 780 | 300 | 110 | 860 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-35ST | 910 | 350 | 115 | 940 | 925 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-40ST | 1040 | 400 | 120 | 890 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-50ST | 1300 | 500 | 125 | 1010 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-60ST | 1560 | 600 | 135 | 1130 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-80ST | 2080 | 800 | 175 | 1180 | 1250 | 750 | 1600 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-99ST | 2600 | 1000 | 190 | 1360 | 1250 | 750 | 1600 | 174 | 74 | 1 |

| Cod. | Code | Image | Active variant image | Capacity (kg) | Capacity (L) | Weight (kg) | Adjustment (mm) | Internal Pipe Ø (mm) | Max opening (mm) | Dimension A (mm) | Dimension B (mm) | Dimension C (mm) | Dimension D (mm) | Dimension E (mm) | Dimension F (mm) | Dimension G (mm) | Dimension H (mm) | Dimension I (mm) | Dimension L (mm) | Dimension M (mm) | Length (mm) | Width (mm) | Height (mm) | Motor | Frequency (Hz) | Speed (rpm) | Blade Ø (mm) | Max. cutting H (mm) | Engine power (cv) | Blade diameter (mm) | Power supply (V) | Useful height (mm) | Total height (mm) | Base diameter (mm) | Diameter (mm) | No. of 200L drums | No. of 1000L tanks | Max load (daN) | Loading opening (mm) | Max liquid temperature (°C) | Max. pipe length (mm) | Cutting width (mm) | H Cut (mm) | Minimal cut | H Wheels (mm) | Technical data notes | Image Name | No. of legs | No. of people | Pubblica nel sito web | Min. capacity (kg) | Max. capacity (kg) | Min. length (mm) | Max. length (mm) | No. of elements (mm) | Span (mm) | Products | Custom price lists | Request Info |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CL-15ST | CL-15ST | 390 | 150 | 95 | 620 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-20ST | CL-20ST | 520 | 200 | 100 | 700 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-25ST | CL-25ST | 650 | 250 | 105 | 780 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-30ST | CL-30ST | 780 | 300 | 110 | 860 | 920 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-35ST | CL-35ST | 910 | 350 | 115 | 940 | 925 | 660 | 1150 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-40ST | CL-40ST | 1040 | 400 | 120 | 890 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-50ST | CL-50ST | 1300 | 500 | 125 | 1010 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-60ST | CL-60ST | 1560 | 600 | 135 | 1130 | 1050 | 660 | 1300 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-80ST | CL-80ST | 2080 | 800 | 175 | 1180 | 1250 | 750 | 1600 | 174 | 74 | 1 | ||||||||||||||||||||||||||||||||||||||||||||||||

| CL-99ST | CL-99ST | 2600 | 1000 | 190 | 1360 | 1250 | 750 | 1600 | 174 | 74 | 1 |